Table of Content

During milling, the husk is best left as intact as possible while releasing the endosperm within; a largely intact hull will form an ideal filter bed during sparging. Although crushing the endosperm to a flour would technically provide maximum conversion, this is only really useful as a theoretical baseline for percent extraction calculations. Make sure everything lines up and that there isn't any wobble in the drill when it's spinning.

These mills are similar to power generation motors in the sense that they use gravity to turn an object. In this case, you would need several feet of space so that the rollers can be turned as a counterweight falls to the ground. This design will require a gear assembly to optimize rotation as well as to get as much power as possible for turning the rollers.

Compare Products

The best sources of rollers appropriate for use on a grain mill are from a conveyor belt , an old printing press , or an agricultural mill. Obviously, these items can be obtained new from a conveyor/press manufacturer or a farm-supply shop. One producer of roller mills, Jack Schmidling Productions shipped his first 40 mills with used photocopy machine rollers. Some conveyor manufacturers even specialize in stainless steel. Buying new rollers can be expensive, so for reasonable prices check for used or discarded rollers from local manufacturers or at mills, scrap yards, or farm auctions.

When malt is exposed to this heat, it undergoes a chemical reaction in which starches are broken down and sugars are converted to alcohol and carbon dioxide. After the mash has been strained, solids are removed from it. The wort is then boiled before it is removed from the water. The wort is cooled before being placed in a fermentation tank to be fermented. Monster Brewing Hardware specializes in handcrafted grain mills that are made in the USA.

Step 5: Step 5: Test the Grain Mill

In addition, a wider gap setting will place the grain, or the gripping point, closer to this “parallel” crushing surface. Traditionally, grain was crushed on stone flour mills, though with more damage to the husk. I asked a local memorial shop about turning granite rollers around a metal shaft. Anyone considering this approach should ensure that only nontoxic methods are used to shape the stone. Suitably hard stone or concrete should work if the equipment, materials, and skill are available.

Do not compromise on the quality of your beer and stick to brewing with the freshest ingredients. One of the best ways to guarantee that is if you do it by yourself. Instead of purchasing pre-milled grain, just mill your own grain and brew it right away to retain maximum freshness.

Northern Brewer Hullwrecker 2-Roller Grain Mill with Metal Base and Handle

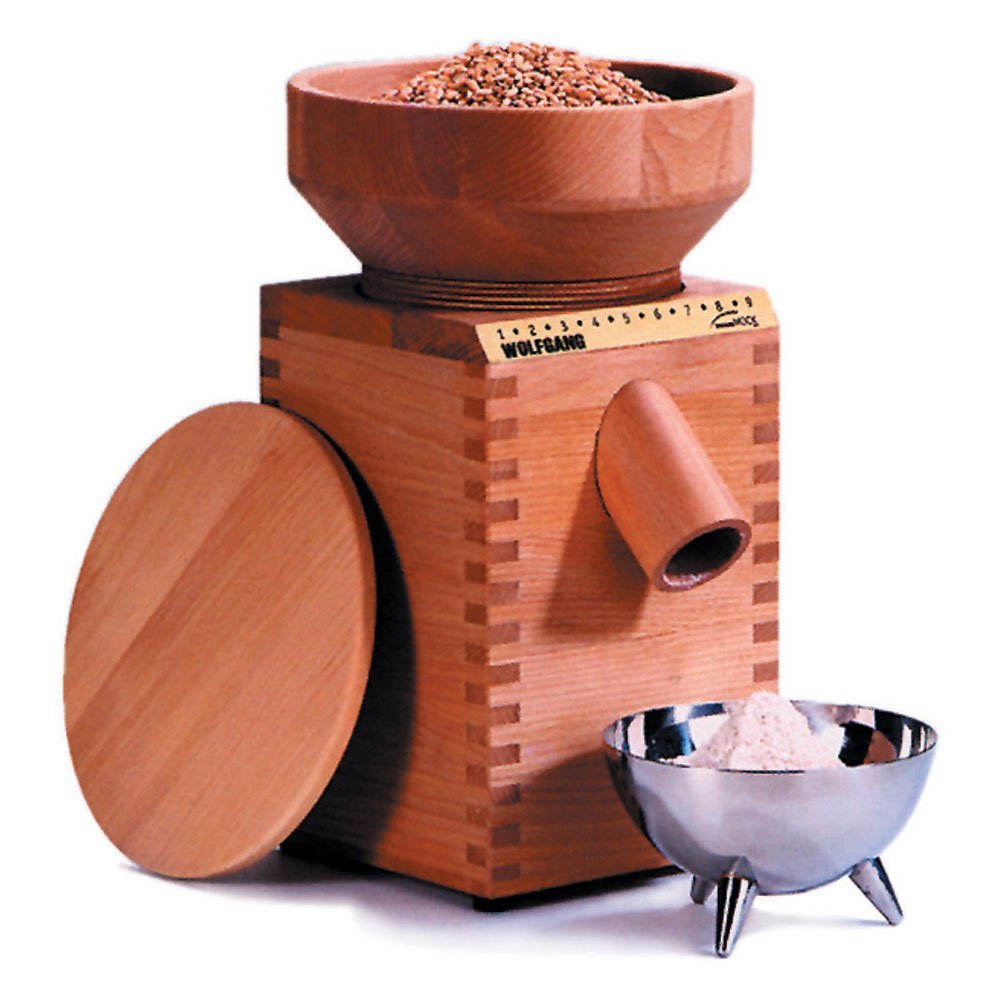

The base of a grain mill is usually made of wood and is used to place the mill over a receptacle, like a brew bucket, to catch the milled grain. Again, not all mills come standard with a base so make sure to check with the supplier. A hopper is a funnel-shaped compartment that holds the grain to be fed to the mill. Normally they’re included with the purchase of a mill but it’s always a good idea to double-check.

You can store unmilled grain for about a year in a sealed container or grain bag. Homebrewers have relied on The Barley Crusher for years. Its simple design and affordable price continue to make this mill one of the best entry-level two-roller grain mills.

The frame is a squared “C” shape, used along with two pieces of angle iron to form slots along which the square bearing housings of the follower roller can run for adjustment. The follower roller had to be adjusted at an angle to form one of two 8-in. To counter the limitation of rollers with small diameters, home brewers have turned to texturing their rollers to better grip the grain. This texturing enables home brewers to achieve a good crush. When power is supplied directly to only one roller, a few different methods are available for effectively transferring the power to the second roller.

Many people are surprised to find out that grinding grains and corn can produce quite a bit of dust. To reduce this problem as much as possible, make sure that the body of the mill, grain, and flour hoppers all fit together tightly. You can use caulk and sealing agents to help with cracks and other areas where dust can get through. The last thing you will want to do is invest in building a larger grain mill with metal rollers only to have the rollers develop rust or some other form of corrosion. By the same token, you will not want wooden rollers to rot or stone ones to develop moss or algae buildups.

So, you can see where something simple like crushing your grain with a homebrew grain mill can get complicated when we start talking about efficiency and stuck sparges. Have you ever mixed flour and water as a kid to make glue? The process of adding hot water to the top of the grain bed to rinse the grains as we lauter is called sparging. This video describes in detail how to build your own grist/malt roller mill for your microbrewery or brewpub. An additional consideration for a driven-roller mill is the addition of a spring-loaded adjustment mechanism.

To achieve the best flavors, you can always grind the day you are planning to brew. Does your homebrew supply shop charge extra to crush grain? Many shops charge a flat fee or price per pound to crush grain. Choosing the right grain mill is an important decision for a homebrewer.

He reports that glazing over with malt components on the grinding surface and tearing of the husks have been the only concern of otherwise successful crushing sessions. If you wish to construct or purchase a two-roller mill, keep in mind that its design must yield a high-quality crush within a reasonable amount of time and effort. Before delving into the all-important rollers, let’s examine the other components. INCLUDES a custom-designed all metal base that fits perfectly on any standard 5 or 6.5 gallon bucket. The available models can hold anywhere between 10 and 40 pounds of grain.

No comments:

Post a Comment